Removing a screw with a stripped head can be a frustrating experience, as the damaged screw often seems impossible to grip and turn. However, with the right tools and techniques, it is possible to remove a stripped screw and complete the task at hand. This article will explore different methods of removing stripped screws, providing practical solutions for those who encounter this common issue.

In order to successfully remove a stripped screw, it is important to understand the underlying causes of the problem. Screws can become stripped when their heads are damaged, often due to the use of improper tools or excessive force. Once a screw head is stripped, traditional screwdrivers become ineffective, and alternative methods must be used to grip and turn the screw. The following techniques will address various approaches to removing the stripped screw, helping to ensure that the task can be completed efficiently and effectively.

Tools and Materials

To successfully remove a screw with a stripped head, you will need the following tools and materials:

- A screwdriver that matches the original type of screw head (flathead, Phillips, etc.)

- A flathead screwdriver for creating a new slot if necessary

- A rubber band

- Drill and small drill bits for preparing the screw for an extractor

- An appropriate screw extractor

- A hammer, to gently tap the screwdriver or extractor in place

- One or two drops of liquid (water, oil, or another lubricant)

- Abrasive powder such as salt or sand to increase grip

Having these items prepared in advance can ensure a smoother and more efficient process. It is also essential to work with caution and patience to avoid causing any further damage to the screw or the surrounding material.

Method 1: Using Pliers

When dealing with a stripped screw head, one of the simplest techniques to remove it is using a pair of pliers. This method offers a secure grip and allows you to apply adequate torque to turn the screw. To use pliers, follow the steps below:

First, select the appropriate type of pliers for the task. Locking pliers such as Irwin Vice-grip pliers are highly recommended, as they provide the most secure grip. Needle nose pliers can also be effective, especially for small screws in tight spaces.

Next, open the pliers and grip the sides of the raised screw head firmly. Ensure that the pliers do not slip off the screw as you turn it. If the screw head is too flat, try using a rubber band or a piece of steel wool to improve grip.

With the pliers securely gripping the screw head, turn the screw counterclockwise. Apply steady pressure and keep turning until the screw is completely removed. It is important to be patient during this process, as too much force may cause further damage or deform the screw head.

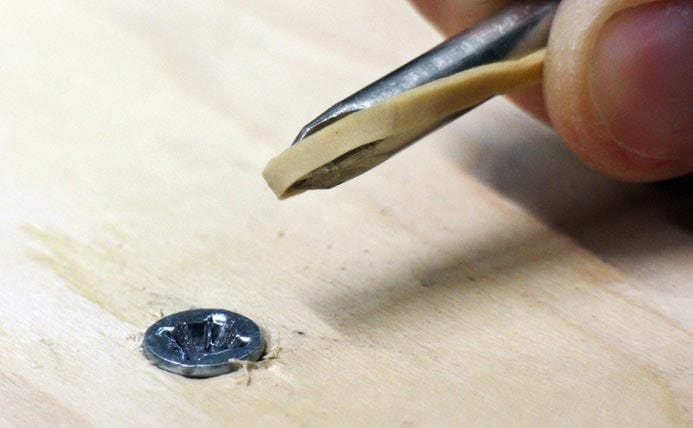

Method 2: Flathead Screwdriver and Hammer

Another effective technique to remove a screw with a stripped head involves using a flathead screwdriver and a hammer. This method is particularly useful when the screw’s slots are too worn or damaged for a regular screwdriver to grip effectively.

First, select a flathead screwdriver that fits the entire hole of the stripped screw head. Ensure that the screwdriver is narrow enough to fit inside the hole without causing further damage. Place the screwdriver into the screw head and ensure it’s seated firmly.

Next, gently tap the base of the screwdriver using a hammer. This step will help to drive the screwdriver deeper into the screw head, creating a better grip. Avoid using excessive force, as this could further damage the screw or surrounding materials. Once the screwdriver is firmly lodged in the screw head, apply downward pressure while simultaneously turning the screwdriver anti-clockwise to unscrew the damaged screw.

It is essential to maintain steady and consistent pressure while turning the screwdriver to prevent slipping and causing more damage to the screw head. If the screw remains difficult to remove, you may need to use a more advanced technique, such as cutting a new slot for improved grip.

Method 3: Rubber Band Trick

The Rubber Band Trick is an ingenious method for removing a screw with a stripped head. This technique utilises the friction between the rubber and the screw, which helps to grip the damaged head and remove the screw.

To use this method, follow the steps below:

- Choose a rubber band that is wide, flat and flexible. Ideally, the rubber band should be slightly larger than the screw head.

- Place the rubber band on top of the stripped screw head, making sure it covers the entire surface.

- Press down firmly on the rubber band with your screwdriver. The screwdriver type (flat head or Phillips) should match the screw head design.

- While applying pressure, slowly turn the screwdriver counter-clockwise. The rubber band should grip the damaged screw head, allowing it to turn and loosen.

- Continue turning the screwdriver until the screw is completely removed.

If the rubber band trick doesn’t work initially, consider the following alternatives:

- Create more grip by using multiple layers of rubber bands on the screw head.

- Try deepening the screwdriver slot with a metal-cutting disk or similar tool before reattempting with the rubber band.

The Rubber Band Trick is an effective and simple method for removing a stripped screw without causing further damage to the surrounding material. With a little patience and the right tools, this technique can help solve the common problem of dealing with damaged screw heads.

Method 4: Using a Screw Extractor

Removing a screw with a stripped head can be a frustrating task. One effective method to tackle this issue is by using a screw extractor. A screw extractor is a handy tool designed specifically to remove stubborn screws with damaged or stripped heads.

Before you begin, ensure you have the right size screw extractor bit for the screw you are trying to remove. It’s essential to choose the correct size, as using the wrong size could cause further damage to the screw. Screw extractor sets are available at most hardware stores.

Now that you have the appropriate tool, follow these steps to remove the stripped screw:

- Drill a small guide hole in the centre of the stripped screw head. Be careful not to apply too much force, as this could cause additional damage to the screw. The guide hole will help the screw extractor to grip the screw more effectively.

- Insert the screw extractor into your drill driver with the burnishing end facing out. Set your drill driver’s transmission to reverse mode, as the extractor works by turning the screw counterclockwise. Line up the extractor bit with the guide hole you created earlier.

- Apply steady and slow pressure as you begin to drill into the screw. The extractor’s unique design will grip the screw’s damaged or stripped head, allowing it to turn counterclockwise and be easily removed from the material.

Remember to exercise patience and caution when using a screw extractor. Forcing the extractor or using the wrong size bit could result in further damage to the screw, making it even more difficult to remove.

Method 5: Left-Handed Drill Bits

Left-handed drill bits are an effective method for removing stripped screws. These drill bits are designed to turn in a counterclockwise direction, which is opposite to the usual clockwise direction of standard drill bits. The reverse action of a left-handed drill bit can catch onto the stripped screw and help unscrew it as the drill bit penetrates the screw head.

Before starting, make sure to use a centre punch to create a small indentation in the centre of the stripped screw head. This will help to guide the left-handed drill bit and ensure it stays in position during the drilling process. Place the left-handed drill bit into the drill’s chuck and tighten it securely. Set the drill to rotate in reverse, or counterclockwise.

Now, apply steady pressure and slowly start drilling into the centre of the stripped screw head. Maintain a constant pressure and keep the drill running in the reverse direction. As the drill bit penetrates the screw head, it may catch onto the screw, causing it to loosen and unscrew.

If the left-handed drill bit is unable to remove the stripped screw, you can also try using a screw extractor in combination with the drill bit. A screw extractor is a specialised tool designed specifically for removing damaged screws. Insert the screw extractor into the hole created by the left-handed drill bit, tap it gently with a hammer to ensure a firm grip, and then turn the extractor counterclockwise. This should help to remove the stripped screw efficiently.

Remember to work carefully when using left-handed drill bits or screw extractors, as improper use can cause damage to the material surrounding the stripped screw.

Safety Precautions

When attempting to remove a screw with a stripped head, it is essential to take several safety precautions to avoid injury and minimise damage to the surrounding material. Implementing these measures will ensure a smooth process and a successful outcome.

Firstly, it is crucial to wear appropriate personal protective equipment (PPE) when working with tools and hardware. This includes wearing safety goggles to protect your eyes from flying debris and attaching a dust mask to prevent the inhalation of any hazardous particles. Additionally, wearing gloves can protect your hands from sharp edges and improve your grip on the tools.

It is also vital to choose the correct tools for the job. Using the wrong size or type of screwdriver can exacerbate the problem of a stripped screw head, making it even harder to remove. Select a screwdriver that is closely matched to the size and shape of the screw head, and avoid using excessive force when attempting to loosen the screw.

Remember to maintain a stable working environment by ensuring your work area is clean, well-lit, and free of clutter. This will help prevent accidental slips or falls that could potentially cause injury or further damage to the material. Also, be mindful of the surrounding materials, as applying too much pressure or using the wrong technique can cause additional harm to the surface you are working on.

In instances where you might need to drill into the screw to create a new groove or employ an extractor tool, proceed with caution. Using a steady hand and moderate pressure can prevent the drill from slipping and causing injury or damaging the surrounding area. If you are unsure of your abilities, it may be best to seek the advice of a professional.

Conclusion

In this article, various techniques for removing a screw with a stripped head have been discussed, such as using a rubber band, duct tape, or superglue to provide extra grip for your screwdriver. Additionally, tools like pliers or locking pliers can be used to grip the screw head and apply more torque when unscrewing.

Each of these methods has its advantages and drawbacks, so it’s essential for users to assess the situation carefully and choose the best technique for their specific scenario. Factors to consider include the size and type of screw, the material it’s embedded in, and the tools available.

Remember that patience and precision are key when dealing with stripped screws. By following the tips and techniques mentioned in this article, users should increase their chances of successfully removing a stripped screw without causing further damage to the surrounding materials.

If you’re interested in pursuing a career as an electrician, we offer a range of electrical courses & training aimed at both experienced electricians and new entrants.