The 3 Types of PAT Testers: Their Differences, Uses and Testing Frequencies

Now that you know more about what PAT testing is, you might be wondering about the machines behind these tests for safety.

The first thing to learn about the Portable Appliance Testing process is knowing your PAT testing equipment and how it works. However, how do you know what kind to use?

Choosing the best PAT tester for your portable electrical equipment is one of the first things to work on when adding PAT testing to your routine to maintain appliances.

Let’s discuss the different types of PAT testers and how they’re used to help you know when to use them for your PAT testing procedures.

The 3 Types of PAT Testers

Many professional PAT testers and PAT testing equipment can help you perform different PAT testing procedures.

Each tester adheres to the regulations, allowing you to fulfil your legal requirement as a business. Any competent person can operate formal visual inspections and portable appliance testing as needed.

However, the real question is which one should be used to test your appliances?

These are the three kinds of PAT testers commonly used to help you find the right PAT tester for your needs.

Pass / Fail PAT Testers

The most basic entry-level PAT testers display the simple pass/fail indication based on the pre-set values. They’re the easiest to operate and can give simple results when PAT testing.

Most testers under this category can conduct essential tests to ensure the used appliances are safe. These include earth continuity, insulation resistance, and polarity of the detachment in the main chords.

Battery-powered testers can also fall in this category, providing the primary pass/fail test results on top of doing a few different tests. It includes testing the extension leads of a machine.

The downside of these PAT testers is their limit. They’re only recommended for low-volume PAT testing. Results are also more vague compared to the advanced testers.

If you’re only testing a few appliances at a time and want to ensure their functionality, this beginner type of tester may be the best choice.

Advanced PAT Testers

An advanced tester can display more detailed results when testing an appliance. This type of tester usually requires a qualified technician to jot down and interpret its data to rate the device properly.

It can work with earth continuity tests, lead polarity tests, earth leakage tests, insulation resistance tests, and fuse integrity. It also has automated testing that allows the test results to be automatically collected and stored.

Most advanced testers can also work on different appliance factors, from RCD, which will be discussed later, to flash testing.

You can also get downloadable PAT testers, which are even more advanced than the previous ones. A downloadable tester can easily transfer any data collected during testing onto your computer or digital database.

If you work in high-risk environments or need to occasionally test several appliances, it’s best to consider getting one of the more advanced PAT testers.

RCD Testing

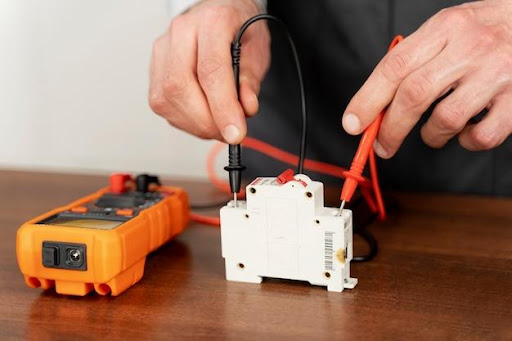

A residual current device, or RCD, is used to test and disconnect the circuit should there be any problems. It’s based on the line conductor and the neutral conductor, which is constantly monitored by this device.

If the current is lost, it may go to the earth. This fault can be from the appliance’s installation process or other complications in the circuit.

It’s the RCD’s job to break that current to protect the user from any electric shock or other possible dangers from your appliances.

These devices are best used in high-risk areas, like bathrooms, since sockets and appliances can be easily exposed to hazards in these places. Having an RCD keeps everything in check and does the job of safely shutting a current down for you.

Different types of RCD testers can be differentiated and identified based on their portability or how they’re fixed onto an electrical appliance.

Fixed RCDs

This type of RCD PAT tester is found in the consumer unit or fuse box of appliances. It provides the highest level of protection and can protect an individual or different groups of circuits.

It also protects all wiring, sockets, and any appliances connected to it.

Socket-Outlet RCDs

These types of testers are built into a special socket outlet and take the place of a standard socket outlet.

Unlike the previous RCD test, this device can only protect what is plugged into the socket and the person in contact with the faulty electrical equipment.

Portable RCDs

These types of testers are plugged into a standard socket outlet. Compared to the other two, which are built-in, this type can be swapped between the different outlets of homes and workplaces.

Like the socket-outlet RCD test, it can only protect the equipment plugged in and the person in contact with the appliance.

What are PAT Testers?

PAT testers are the devices used to test appliances’ safety and functionality. They help determine if an appliance needs to be repaired or replaced to keep any establishment safe.

You’ll have to plug the appliance onto the tester during the testing procedure.

It has a test lead connected to the earth point and metallic parts to help determine if the appliance passes the test. It can consider more factors, depending on how advanced the tester is.

There are different kinds of PAT testing depending on the electrical appliance you’re working with. It’s a step up from manual testing and running a visual inspection, allowing you to look more into the appliance.

While working on a PAT testing certification, you’ll learn that each type of tester has its significance and the different safety measures involved in the procedure.

Usually, you would need basic training to operate a simple PAT tester. However, other advanced testers may need a proper PAT testing course since their results are more detailed. It also ensures that you’re testing the appliances properly.

Benefits of PAT Testers

PAT testing is one of the many ways to promote electrical safety, detecting problems your equipment may face.

While it is easy to pay a competent person or company outside of an establishment, owning your testing equipment and having someone who can operate it has a lot of benefits.

These are the benefits of having and using a PAT tester.

Investment For Safety

PAT testing is one of the easiest and most cost-efficient ways to ensure safety in an establishment.

Using a PAT tester, as the appliance’s manufacturer requires, can help monitor if your equipment is a hazard.

Prevention and taking the necessary actions to keep establishments safe is the best way to avoid any accidents that can be inflicted on workers and customers.

Follow Legal Requirements

Laws in place make businesses liable for any danger caused by potentially dangerous equipment, especially from accidents caused by electrical equipment.

While PAT testing isn’t a legal requirement, ensuring all equipment is safe is. The best way is to conduct frequent tests and prevent accidents by keeping your appliances up-to-date.

It saves an establishment a lot of money in the long run, especially since they wouldn’t have to work under the constant risk of having to cover damages caused by faulty equipment.

Factors to Consider When Choosing PAT Testers to Use

With the many kinds of PAT testers, it can be tricky to find the best one. However, these testers do have their strengths and weaknesses.

There are many properties when looking for PAT testing equipment that can help ensure the safety of an establishment or construction site.

These are the factors to consider before purchasing a PAT tester.

Type of Equipment to be Tested

The type of equipment you’re working with affects the kind of tester you can invest in.

Basic testers may be advisable for smaller businesses or those needing to check everyday items as a quick and easy safety measure. These testers won’t fare well in places like a construction site or a bustling establishment.

More advanced options are best for PAT testing in high-risk environments requiring more accurate results.

A PAT tester should also be able to test surge-protected extension leads, RCDs, and more, depending on how hazardous your equipment is.

Frequency of Testing

Different types of electrical appliances require different testing frequencies, depending on how dangerous it is. It can also depend on the class and category of portable appliance you’re working with.

Some appliances might need more visual inspections than PAT tests. However, more dangerous equipment would require a formal visual inspection and a proper PAT test, especially if used often.

You can consider the following, as recommended by the Health and Safety Executive, on how frequently you should test your appliances:

- The history and age of the electrical appliance

- The manufacturer’s recommendations for testing and maintenance

- How often is the electrical appliance used

- Effects of previous modifications and repairs

- Possible misuse of equipment

- Risk level of the appliance’s environment

If your devices must be constantly tested, your PAT tester should be suitable for multiple uses without compromising accuracy.

How many appliances you use in a specific establishment can also affect frequency since these electrical appliances can be connected to one circuit.

Budget

There are no actual costs for PAT testing since it can vary on its technology and what it can test out in an appliance.

If you’re the type to conduct the occasional PAT test for safety reasons, spending a little extra for the most accurate results is best.

Investing in PAT testing equipment is best if a business frequently needs PAT testing for its appliances. Having someone receive proper PAT training is also included in this investment.

PAT testing is easy to learn and can be done by anyone, even if they’re not an electrician. Most people are easy to train for a basic PAT test, especially to meet the frequent testing needs of some establishments.

It would be best if you also considered the need for a duty holder for some testing equipment and any insurance requirements that can come with buying a PAT tester.

Downloadable PAT testers may be more expensive. However, they can give some of the most accurate results. If you only work with low-volume testing, more basic PAT testers or manual PAT testers may be worth it.

User Experience

Different brands provide varying experiences to their users. They all function differently and can help you take the necessary steps to improve an appliance’s performance.

It’s best to look through the different forums and get duty-holders opinions on how this equipment performs during the PAT testing process.

Product reviews can also help get the opinions of more casual equipment users, especially if you’re a beginner with PAT testing.

Factors of Appliance to Be Tested

Different types of tests can be conducted on your electrical equipment. It also affects the kind of tester you invest in.

For example, if you frequently need an insulation resistance test, you need a test voltage of 250V. It may be different for earth bond tests or a flash test.

Most basic PAT testers can do general tests, including insulation resistance, lead polarity, and the earth continuity test.

Advanced testers would do what basic PAT testers do, but they can be more complicated and would need a professional PAT tester’s opinion on what to do with the appliance.

Advanced vs Basic PAT Testers

Knowing whether to invest in advanced or basic PAT testing equipment is also an important factor to consider. Besides the features, it can also affect the price you’d have to pay for a reliable test.

Sometimes, you might only need a basic PAT tester with a simple pass/fail mechanism. They can perform the most critical tests to ensure an appliance’s safety.

Other times, advanced or downloadable testers may be necessary, especially if you’re working with more equipment with factors such as flash testing and extension leads.

Frequently Asked Questions (FAQs)

You might have more questions about PAT testers and their different types.

We’ve gathered the most common questions to help you further understand them.

What Types of Equipment Can Undergo PAT Testing?

Portable appliances are divided into classes and categories, depending on the risk of using them. Other factors, such as environment and frequency of use, can also be considered when seeing if an appliance needs a PAT test.

Class I equipment is the most common portable appliance requiring periodic PAT testing. They only have basic insulation, which requires constant monitoring and the regular full PAT test to ensure safety.

Class II appliances are double-insulated equipment, which makes them less dangerous than the previous ones. However, the occasional formal visual inspection and PAT test would also be advisable, especially in high-risk environments.

Class III appliances are the least dangerous class of equipment. While they don’t need the full PAT test as frequently as the previous classes, running the occasional PAT test as a safety measure is still good.

As for categories, they can also affect the PAT testing process. Some categories, such as handheld electrical appliances, chargers, and cables, may require more frequent visual inspections and PAT tests than others.

While a Class I appliance may be used in low-risk environments, it would still need annual PAT testing, unlike a Class III appliance, which only requires a visual inspection unless necessary.

Should a PAT Tester Be Calibrated Annually?

Calibration is essential to ensure the accuracy of your test results. Accuracy in PAT testing is essential to ensure the electrical appliance is safe.

According to the IET Code of Practice, any equipment used to run testing functions for safety should be calibrated annually.

However, it’s also important to consider if there is a reason to doubt your PAT testing equipment’s test results, then you may have to do it more often.

If each test shows similar results, you’re more likely to get more reliable results.

However, if there are differences when conducting PAT tests, your tester may need to be replaced. Testing with faulty equipment can also be a risk to an establishment.

Does a Fixed Appliance Need PAT Tests?

No, fixed appliances don’t need PAT testing. The test is ONLY used for portable appliances.

However, ensuring a fixed appliance is also important and relies more on visual inspections. It’s also covered in an establishment’s legal liability if there are accidents.

Conclusion

PAT testing is one of the many ways to ensure that an establishment only uses safe and fully-functioning appliances.

Finding the best PAT tester is the first step to ensuring your electrical equipment is always ready for the job.