What is Portable Appliance Testing (PAT Testing)? A Beginner Guide for Businesses

Portable electrical equipment is used in different types of workplaces, from a construction site to a hospital. It’s become essential to carry out daily jobs.

Given the work regulations in place, a business needs to ensure that its equipment won’t harm people’s health and safety. That’s where a PAT test, which requires training, comes in.

However, before undergoing any PAT testing course, it’s essential to understand the concepts behind it.

Here’s an easy guide to help you understand PAT testing and why and how a company or business should undergo a PAT testing course.

What is PAT Testing?

Portable Appliance Testing, or PAT testing, examines ANY piece of portable electrical equipment for defects or damage. A PAT test is done for damages that visual inspections can’t see.

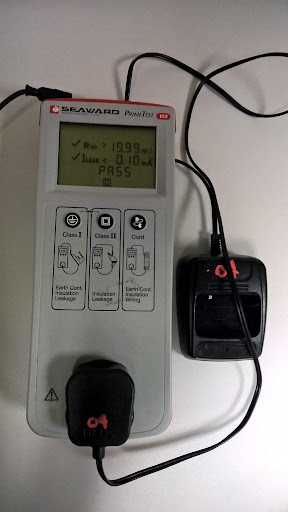

Any advanced inspections may require specialist PAT testing equipment to ensure that appliances won’t be dangerous to the health and safety of their users.

Most hazards can be found during a visual examination of the appliance in question. However, there are times when a formal PAT inspection is required to find any underlying damage.

Many appliances, such as fixed appliances, IT appliances, cables, and more, may require PAT testing. It’s needed for any transportable electrical equipment without a fixed installation.

PAT testing involves regulations and certification to ensure electrical equipment safety for daily use. Having a proper electrical maintenance regime is a great way to stay on top of any potential issues.

History of PAT Testing

PAT testing of electrical equipment was already standard even before the introduction of the Electricity At Work Regulations 1989 (EAWR 1989).

Those in charge of testing these appliances would label them with “passed,” “tested for electrical safety,” or “do not use after…” depending on the results.

Its process used to be known as the “In-Service Inspection & Testing of Electrical Equipment.” It was further encouraged as laws emerged to increase the liability of employers.

PAT testing is done in the United Kingdom, Ireland, New Zealand, and Australia.

Why Do I Need PAT Testing?

It doesn’t matter if you work in a construction site, a restaurant, or a hospital. All industries rely on electrical equipment to perform their daily tasks. Even self-employed people make use of them.

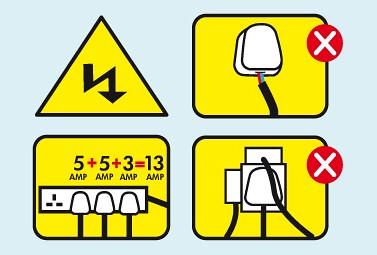

Any use of electrical equipment also comes with risks. If you work with a faulty or poorly-maintained device, you risk getting an electric shock, burns, or even fires.

To protect workers and anyone using said devices, PAT tests are encouraged by the government as an easy way to check these pieces of equipment.

It’s best to conduct the necessary tests on these portable appliances as a precaution and for the health and safety of your workers.

You don’t always have to be the most competent person to check on your portable appliances. Anyone with basic training in using these devices can also know the basics of PAT testing.

It’s also important to have insurance for a PAT test, along with a few requirements. It helps you stay prepared in case you need to perform the test.

Is PAT Testing a Legal Requirement?

No, PAT testing isn’t a legal requirement. However, many laws ensure the health and safety of everyone in the workplace. These prevent people from getting injured at their place of employment.

After all, poorly maintained or faulty electrical equipment can lead to significant burns, electric shocks and building fires, putting people at great risk.

The Health and Safety Executive, founded in 1974, states that employers must ensure their workers’ welfare, health, and safety, especially around the necessary electrical equipment.

It’s further backed by the Electricity at Work Regulations that give employers legal responsibility for any incidents that might arise from equipment apparently failing.

Failure to follow these Executives can lead to fines and legal consequences. These are usually avoided by doing an occasional PAT test and repairing or replacing equipment as needed.

PAT tests are the best way to ensure that the electrical equipment and appliances tested are safe for daily use. It’s a simple and cost-effective way to meet the legalities of the previously-mentioned laws.

Steps Involved in PAT Testing

Generally, different types of PAT testing depend on the electrical equipment you’re working with. They can also involve various testing equipment and records to differentiate each one.

However, there are also general PAT testing procedures that everyone must follow to ensure the health and safety of every employee. Knowing these is mandatory, especially if you often use these electrical appliances.

These are the steps involved when conducting your own PAT testing.

Step 1) User Checks

Employees are required to learn how these machines work to use different portable appliances. This includes knowing how a device should and shouldn’t look or function.

You don’t need to be a qualified PAT tester to know if a device has any damages. Anyone can do it, especially those who use the appliance daily.

User checks are usually done by simply observing the surface of the appliance. These don’t need to be recorded since any visible damage before a formal PAT test is an automatic fail.

It also includes checking if cables are trapped under your desk or potential water or fire hazards. These factors are easily avoided without the need for a PAT test.

Any competent person can do this step, especially since it’s the employer’s responsibility to train their workers on how their appliances work. It’s the most basic requirement for employee health and safety.

If there isn’t any damage, you can continue using the device. However, you sometimes need a more detailed PAT test to know if your appliance is still in top condition.

Step 2) Formal Visual Inspection

Prior to any use of a portable appliance tester, it’s vital to perform a visual inspection of your electrical equipment. It’s part of the PAT testing regulations since machines cannot track everything.

This visual inspection process can flag up to 90% or most electrical safety defects. Any business staff member with relevant training or a professional can do this.

SAFETY NOTE: Ensure appliances are turned off and unplugged before conducting a visual inspection and electrical testing.

If there are signs of damage in any of their parts, you must have them replaced or repaired since they will threaten health and safety.

Any formal visual inspections are recorded for future reference, especially since businesses can work with more than one PAT testing specialist or other relevant personnel.

The formal visual inspection requires checking electrical appliances down to their smallest parts. These are the things to add to your checklist during visual inspections.

The Cable

Check for any physical damage on the appliance’s cables. This includes abrasions, frying, and cuts. Even the most minor damage can make appliances dangerous for use.

You might also require leakage current testing to ensure power is appropriately and safely transported from the main socket to the appliance.

Any exposed wiring is an automatic fail and must be replaced before use.

The Plug

It’s important to check the plug for physical damage, especially since it’s the part we hold onto when plugging an appliance.

Keep an eye out for signs of damage, such as cracks, bent pins, and burns. These immediately make the plugs more dangerous to hold.

It’s also important to check if the live, neutral, and earth conductors are connected tightly to the relevant terminals.

Main Socket

The main socket isn’t part of the PAT test. However, it should still be included in your visual inspection since it can still threaten health and safety when damaged.

It’s a step often connected to the cable check since this is where it’s plugged into.

Look for signs of cracking, overheating, and loose fittings. It’s also important to check if its shutter mechanism is working well.

The Electrical Appliance

It’s important to conduct a visual examination of the electrical appliance itself. There may be apparent damage that could be seen without the use of extra equipment.

Before any PAT test, check for burns, cracks, corrosion, and present wear and tear in the appliance’s casing.

Residual Current Device (RCD) Checks

A residual current device is an integral part of an appliance that can deactivate it in a matter of seconds if there is a fault.

They’re fitted with a test button. It trips the current flowing to the live conductor if there is a fault in the electric currents.

Before conducting a PAT test, make sure that the RCD test button is working correctly, especially since this is an important safety feature for electrical appliances.

Environmental Checks

Doing a risk assessment of your environment is essential for visual examination. There are times when an electrical safety defect can be affected by the appliance’s surroundings.

Check for any trip hazards around the area. It can include cables and overloaded extension leads, which are high-risk and can affect other stationary appliances.

You can consult the Maintaining Portable Equipment Guide by the HSE to help keep each electrical appliance and its environment safe.

Step 3) Manual Examination of Equipment Using PAT Test

This step requires using a PAT tester and taking down proper records for future reference. You would have to do a physical test along with a manual examination using your tester.

These include more complicated processes that necessitate the use of portable appliance testers. They include insulation resistance tests, an earth continuity test or screen test, polarity testing, lead polarity, and more.

These tests vary in purpose, which can be affected by the class and kind of appliance you’re working with.

For example, given their higher voltages, you would need to perform insulation resistance checks or a leakage current test for Class 1 and 2 appliances.

On the other hand, a Class 3 appliance may not require an insulation test because it has more stable insulation. However, its wires and other parts can still be PAT tested as a precaution.

Hiring a professional and qualified PAT tester is recommended to achieve the safest results. The cost of PAT testing is a small price to pay to protect employees.

Benefits of PAT Testing

PAT testing can contribute significantly to a business and how it conducts everyday tasks.

Some people might skip it because of the added cost or equipment required. However, PAT testing is essential for any business to conduct.

These are the benefits of PAT testing and using a portable appliance tester as needed.

Reduced Risks

The best way to prevent any major accidents is to take precautions. PAT testing is the best way to reduce risks when dealing with electrical appliances.

Routine electrical testing will help you know which equipment needs repair or replacement.

Knowing when the device would need a PAT insulation test, continuity test, or any other type of relevant testing can also help you adjust your equipment accordingly.

PAT testing is also more affordable than any damage faulty appliances can do to a business.

Health and Safety

All businesses should care for the health and safety of their workers, especially since they keep the gears of industry moving.

Working with any electrical appliance is a constant risk, especially with all the possible dangers that can come from it.

Doing the occasional PAT test can ensure that these appliances won’t pose a risk to the health and safety of people in your workplace. It prevents additional bills that can result from on-site accidents.

Legal Responsibilities

Having your appliances PAT tested is the best way to stay compliant with the government’s different health and safety protocols.

It’s the easiest way to test appliances and ensure that they’re safe for daily use. It’s crucial, especially for workplaces that are constantly exposed to the risk of electrical appliances.

If you’re sure that your appliances are safe for use, you’re less likely to be worried about the authorities. There are fewer chances of having legal issues and fines when everyone is safe.

Frequently Asked Questions (FAQs)

You may have more questions about PAT testing and why it’s important for the health and safety of employees.

We’ve gathered the most common questions to help you further with your research.

What Sort of Electrical Equipment Requires PAT Testing?

Electrical equipment can be categorised into 3 classes; Class 1, 2, and 3. Class 1 appliances are the most high-risk electrical equipment, while Class 3 are the least.

Electrical appliances are PAT tested based on their class. It helps to know the procedures needed and their importance since electrical tests vary.

- Class 1: These appliances rely on earth continuity because they use only basic insulation. It needs both a visual inspection and a PAT test, especially the earth continuity test, to ensure electrical safety.

- Class 2: These appliances have extra insulation and don’t require an earth for protection, making them much safer. It’s recommended to have the occasional insulation PAT test for these types of electrical equipment.

- Class 3: These are not high-risk appliances since they work with a low voltage, making them one of the safest categories. While it doesn’t require regular PAT testing, chargers, and wiring may need to be PAT tested as a precaution.

Class 1 and 2 devices may also require voltage-limiting devices to prevent major damage. These are also factors to consider when the appliance is being PAT tested.

Some fixed appliances may also be required to be PAT tested. If you can unplug and move the appliance, it’s best to run it through a portable appliance test occasionally.

Note that classes and categories may also affect the PAT tests you must conduct on the appliance. These also include PAT testing safety and any PAT testers who may be involved.

What is the Ideal PAT Testing Frequency for Electrical Appliances?

There is no specific set of rules regarding the frequency of testing equipment. Laws for work regulations only state that the level of precaution should be appropriate to the risk of portable electrical appliances.

However, equipment manufacturers recommend testing equipment frequently to ensure their safety. It’s important to consider the following criteria:

- The category of the appliance tested

- Electrical class of the appliance

- The risk level of the work environment

Under the appliance’s properties, it’s also important to consider the following to affect your PAT testing frequency and visual inspections:

- History and age of the electrical appliance

- Manufacturer’s recommendations for maintenance and testing

- Frequency of use

- Effects of repairs and modifications

- Foreseeable misuse of the electrical appliance

For example, if you’re working on a construction site, you might have to do more PAT tests, like an insulation test, since it’s a high-risk environment that can cause more damage to the appliance.

Even if you’re working in low-risk environments, you could still do PAT tests often if your appliance is often used.

Since it’s important to maintain electrical equipment in top condition, PAT testing equipment should be done as frequently as possible. Having a set regime can reduce risk and promote better health and safety conditions.

Conclusion

Whether you’re working with portable or stationary appliances, checking their condition is important to keep businesses going.

A routine test for your electrical installations is a must to ensure the health and safety of anyone using it. Portable appliance testing is one of the best practises to add to your routine.